OVERVIEW

Our Engineering Analysis Facility specializes in designing and creating custom tools, machines, and fabrication components tailored to our customers' specific manufacturing needs. By leveraging advanced engineering analysis and cutting-edge technology, we transform conceptual designs into practical, high-quality solutions. Whether it’s developing specialised tooling, custom machines, or bespoke components, we work closely with our customers to ensure the final product meets their exact specifications and operational requirements. In the context of making tools, fabricating components, or designing machines, this facility understands the design, functionality, and materials of the item and then creates or improvise it.

Precision Measurement

& Tolerance

This phase is a critical first step in our engineering analysis process, where we establish the foundation for the entire project. This could involve reproducing an existing tool, improving a part for enhanced performance or durability, reproducing obsolete components that are no longer available, or designing compatible parts that fit into an existing system or assembly.

The first step is a physical inspection, where we closely analyse the part to identify critical elements such as materials, surface finishes, and mechanical characteristics. This inspection helps us understand the functionality and design intent behind the part, as well as any wear or damage that may affect its performance.

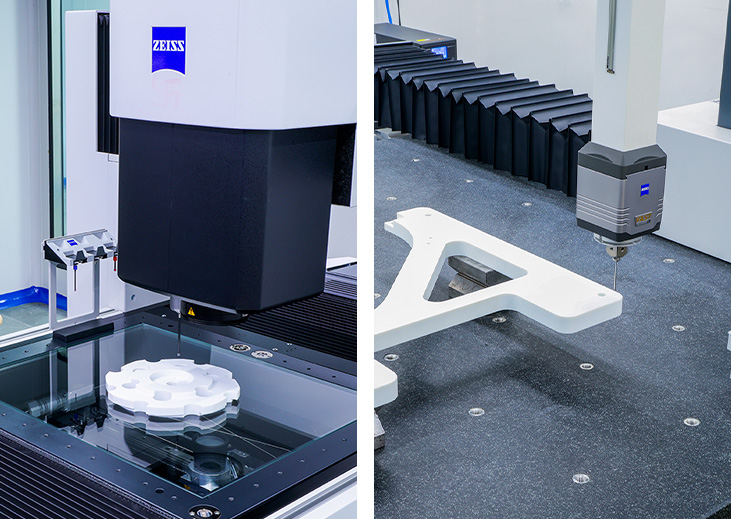

Next, we proceed with precision measurement using a range of advanced tools, such as micrometers, calipers, coordinate measuring machines (CMMs), vision measuring machines (VMMs), 3D scanners and PMI Guns. These instruments allow us to capture highly accurate dimensional data, ensuring that every aspect of the part is meticulously recorded. For machines, this process includes measuring critical dimensions, tolerances, and performing alignment checks to ensure that the part will fit seamlessly within the larger system.

3D Scanning & Modelling (Digitalization)

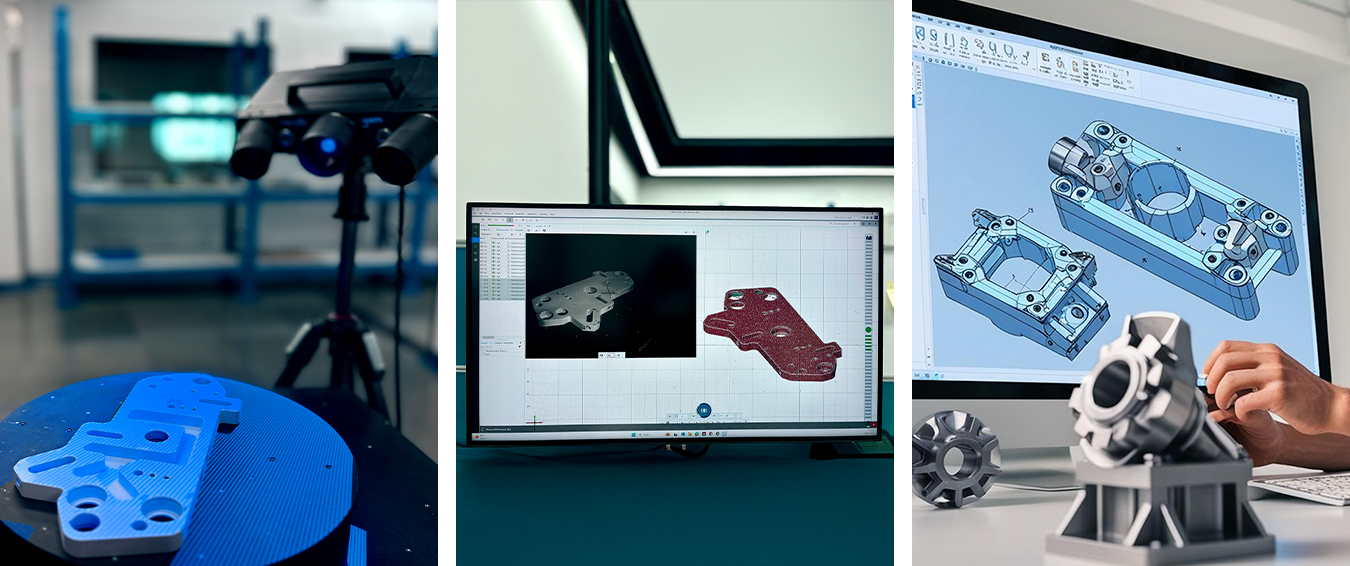

In the 3D Scanning & Modelling (Digitalization) phase, our department leverages advanced technologies to create highly accurate digital representations of the part or tool being analysed. We begin by using 3D scanners, structured light scanners, to capture precise surface details and dimensions of the physical component.

Once the scan data is collected, we move into the CAD modeling phase, where the data is seamlessly imported into Siemens NX, our advanced Computer-Aided Design (CAD) software. This powerful tool allows us to transform raw scan data into precise, highly detailed 2D and 3D models of any part or equipment. This powerful tool enables us to transform the scanned data into a precise and fully editable digital model, ready for further analysis, modifications, or manufacturing.

In certain special cases where the required parts cannot be sent to us by our clients, we offer a convenient solution by sending our 3D scanners directly to their site. This approach fosters stronger collaboration with our clients, providing greater flexibility and improving overall efficiency.

Prototyping & Modelling

In the Prototyping phase, once the final CAD model is approved from the client, we move on to creating physical prototypes of the new or improved tool, machine part, or system. Depending on the complexity of the design and the materials involved, prototypes are created using a range of advanced manufacturing processes.

Once the prototype is made, it undergoes a thorough testing process to ensure that it meets the required specifications. This includes dimensional checks to confirm the accuracy of the prototype against the original design, as well as performance evaluations to assess its functionality under operational conditions. If necessary, we also conduct stress analysis to evaluate how the part holds up under load, heat, or wear over time.

Application-based Engineering Analysis

for Targeted Solutions

We specialize in application-based engineering analysis to provide targeted solutions that address the unique challenges of each industry. Our team uses advanced tools and methodologies to analyze every aspect of a system or process, considering the environment, performance criteria, and operational constraints. Whether optimizing machinery, enhancing system designs, or improving production workflows, we focus on delivering precise, actionable insights that drive tangible results. This application-centric approach enables us to offer customized solutions that not only meet technical specifications but also align with our clients’ strategic objectives, ensuring maximum value and long-term success.

No Blueprint? No Problem! One of the coolest aspects of our engineering facility is the ability to create something that doesn’t have a pre-existing design document. With just a physical part, our team can analyse it and produce a blueprint from scratch!

Knowledge

Nuggets

The accuracy achieved in engineering is staggering. Modern scanning technologies like 3D scanning and CMM (Coordinate Measuring Machines) can capture and create measurements with precision to the micron (1/1000th of a millimetre)!